DOWN HOLE EQUIPMENTS

DOWN HOLE EQUIPMENTS

- Cup Type Tester

- NMDC

As you drill in areas closer to the earth's magnetic poles, it is essential to use a non-magnetic drill collar. Our non-mag drill collars offer strength and hardness while neutralizing magnetic inference. Compatible with standard drill string tools and stabilizers, our non mag drill collars are manufactured to API Spec 7-1. Inventory includes:

- Slick

- Flex

- Spiral

- Pony

- Resistant to stress corrosion in sour gas environments

- Compatible with standard drill string tools and stablizers

- Spiraling available on request

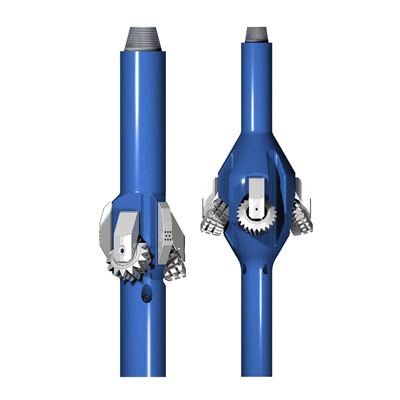

- Under Reamers

- Stabilizers

- Roller Reamer Stabilizer

- Hole Opener

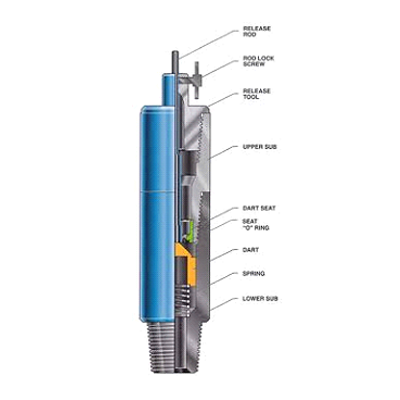

- Drilling Jar

- Drilling Accelerator

- Shock Sub

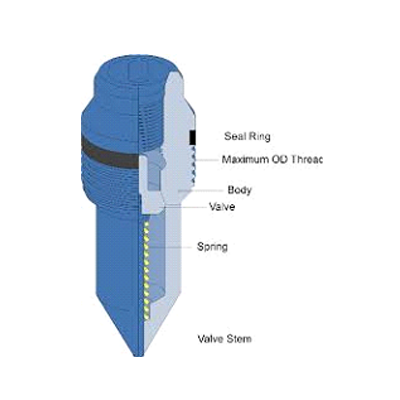

- Back Pressure Valve

- Kelly Valve

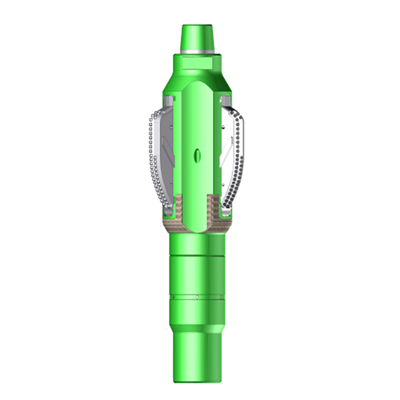

- Full Open Safety Valve

- Lifting Cap & Plug

- Lifting Sub

Cup tester is designed to be attached to the drill string and then lowered into the casing beneath the wellhead to pressure test the blowout preventer stack and the wellhead. When the cup tester is lowered into the casing beneath the wellhead, pressure is applied to either a test pump, or by hoisting type cup after filling the hookup with water.

We treat our non-mag material ID with a shot peening operation to compress the inside diameter which prevents stress corrosion while drilling in H2S environments.

Stabilizers are an integral part of the bottom hole assembly. They concentrate the weight of the drill collars on the bit, stiffen the BHA, and keep the drill collars away from the borehole wall, thus reducing the risk of stuck pipe

3-point or 6-point roller reamers (also know as rotary reamers) are designed for reaming and stabilization in any type of formation. All parts of the tools are made of special alloy steel and heat treated for hardness.

Drilling crews can easily replace any part in the field without the use of special tools.

Reamers are available in a wide range of standard and custom sizes, up to hole size 26″.