TUBULAR HANDLING TOOLS

ELEVATORS

Manual operated elevators are conventionally operated elevators for lifting all existing pipe:

- Collar type center latch A series

- 18° center latch G series

- Collar type side door x series

- Auxiliary S-series

The elevators are suitable for handling casing, tubing, plain upset drill pipe, collar type drill pipe, 18° drill pipe, IU, EU and [EU plpe etc, depending on the type and rating.

Air operated elevators are conventional center latch elevators to which power actuation has been added. This feature permits remote opening of the elevators.

NOV "Y" sen'es elevators are conventional slip type elevators for handling tubing and small casing. They feature a four slip design which give an optimum contact on the pipe to prevent bottle necking and gauge damage.

Center-latch elevators are for handling collar-type drill pipe, casing and tubing. All “A" type elevators are constructed in two halves of practically the same weight, providing proper balance and easier opening and closing.

With Its 125 sTon ( 114 Tonne) capacity the NYC elevator completes the range of Y type elevators for handling either external upset or API collar type casing or tubing.

Size range and capacity:

3.1/2" to 178-89) "7mm) OD. API rated capacity Is 125 s‘l’on (114 Tonne).

The YC elevator is an exceptionally versatile elevator that handles either external upset or API col lartype casing simply by installing the proper size insert-type slips and slip-setting ring assembly.

Size range and capacity:

89) 3.1/2" mm) through 178) "7 mm) caslng. API rated capacity is 75 sTon (68 Tonne)

The HYT elevator is designed to accommodate the widest possible range of tubing

The MYT elevator is a light-weight elevator for medium wells. It handles all tubing within its range with one set of slips, plus reducing inserts. The MYT elevator has four curved slips that form a circle around the tubing. 111is assures an uniform grip with minimum marking of pipe.

G series elevators are constructed in two halves of practically the same weight for better balance, making them easier to handle; easier to latch on and take off the pipe. In open position, a G series elevator hangs ready for closing at any point below the upset of the pipe. Safety features include guarded operating handles to help prevent accidents to operators and an extra handle at the rear of the elevator for easier, safer operation.

SJL and SPL single-joint, center-latch elevators are designed to replace unsafe rope slings for hoisting collaptype pipe into position. The SJL °90 elevator enables the crew to handle pipe properly, help avoid damage to pipe threads and reduce the chances of accident or injury. The SPL elevator is the same as the SJL elevator except that the SPL elevator is designed for use on tapered pipe, conforming to API specifications for extreme line casing.

The X-series elevators handle all sizes of collar-type tubing, drill pipe and casing.

The elevator/spider tool is designed for lifting and suspending tubular goods, from light tubing to heavy wall pipe and drill collars.The main body of these units can be dressed as a casing elevator or as a spider. The upper unit is dressed as an elevator, using a bottom guide and a bell guide. The lower unit is dressed as a spider, using a top guide to aid in centering the casing.The elevator is attached to the derrick traveling block and hook with 1,000 8050500 350 ,250 Tons standard Varco weldless llnks.The spider ca n be placed directly on the master bushing or rotary, assuming flat and sufficient contact surface is assured.

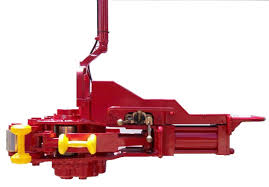

The FM5375/275 is a hydraulic operated power slip which is equipped with replaceable slips and insert carriers to handle casing. The power down force generated allows the FMS to take the torque reaction of the tong when the string weight is not sufficient to resist rotating and eliminates the need for a manual casing tong. The powered down slips allow the first casing joints to be run in with the FMS.

SDS, SDML, SDXL and SDHL rotary slips are for use in API standard insert bowls.Featuring better contact and distribution of load on drill pipe through a superior wraparound configuration and unique insert design, these slips prevent bottle necking and gouging damage.The buttress design of the body segments provides great strength while minimizing weight for ease of handling

CMS-XL slips are manufactured from castings, reinforced to take severe service. The self-centering full wraparound grip prevents damage to casing

Each slip segments are castings with an extra long back to provide maximum support to the circular button gripping elements.

Safety clamps are a convenient way to secure flush tubular products during installation. The MP clamp can act as the last resort, when a piece of tubular slips through the slips. Especially in combination with handslips, the clamp will land on top of the slips, adding extra push down force to the slips and thus stopping the tubular from slipping through the slip

The Baash Ross 200 ton hinged casing spider will fit most casing handling operations. It can be placed on the rotary table, mounted on a platform which replaces the rotary table, or supported by cribbing, depending upon the auxiliary equipment and procedure to be followed.

The Baash Ross type UC3- slips achieves this with many narrow segments. They are hinged together to wrap around the casing and exert a more uniform pressure. With each segment carrying the same load, they automatically center the casing string within the bushing or spider.The UC3- has a 3'tapen

The HT tong is a tool designed for making up and breaking connections of tubular goods, from light tubing to heavy wall pipe and drill collars. There are 7 types, varying in torque capacity from 10,000 to 200,000 lbs/ft (271,000 - 13,56oNm) Covered sizes from 2 3/8” to 17“ , or 36" (HTSO with extended reach)-lnterchangeable lug jaw design permits each tong to handle different sizes of pipe. By installing hinge jaws (available for some models), bigger pipe sizes can be handled. The tongs can be assembled for either making-up or break-o by removing the hanger and turning the complete HT tong over.

Weldless links are forged from a single piece of high-grade alloy steel to provide maximum tensile strength. More weight and “plus-diameter" in critical areas make these links extra strong. Short upper eye design means better balance and easier elevator handling, while reducing wear of the eye section against the swivel bail or body.

The hydraulically powered SSW30 can spin drill pipe and drill collars from 2.778" to 9.1/2" 0.0. with no adjustments necessary. Its abundant power will bump up shoulders tight enough so each joint is quickly torqued. This lightweight tool is narrower and has lower profile than previous spinning wrench designs. It achieves its compact shape by using one large cylinder for clamping.

Efficient method of handling drill collars without having to remove the elevator from the links. The drill collar assemblies are suitable for use in combination with the perfection links. The size range is from 2.7/8" plain to 6.5/8" IEU.